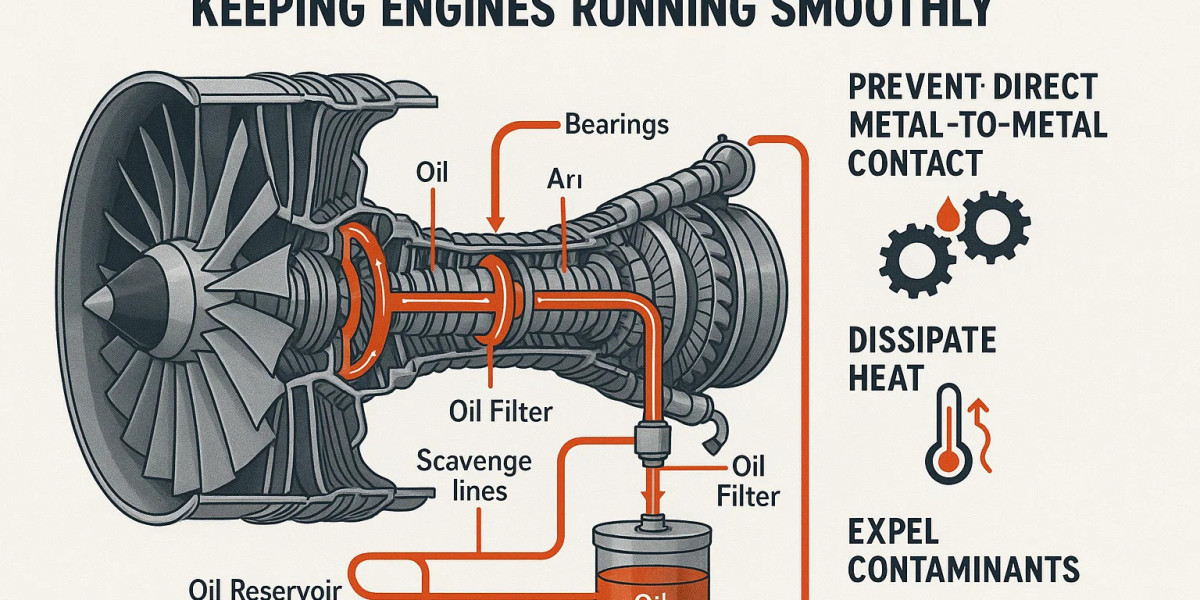

The Science Behind Aircraft Lubrication Systems: Keeping Engines Running Smoothly

Operating under extreme pressures, temperatures, and speeds, aircraft engines are marvels of modern engineering. For these mechanical beasts to perform reliably and safely, one of the most important aspects of engine operation is a well-designed and maintained lubrication system. Aircraft lubrication systems prevent direct metal-to-metal contact, dissipate heat, and expel contaminants. These systems are critical to the performance, efficiency, and lifespan of an engine.

The Role of Lubrication in Aircraft Engines

The simple fact is that friction results from the relative movement of mechanical parts. In the case of aircraft engines, friction can lead to high temperatures, accelerated wear, and ultimately engine failure if left unchecked. The aircraft lubrication system is designed to create a film of lubricant between moving surfaces to dramatically reduce friction and wear. The system also has a role in:

● Temperature Control: Lubricants help to dissipate heat generated within the engine.

● Cleaning: Lubricants flush away contaminants such as metal particles and combustion by-products.

● Corrosion Protection: Lubricants often contain additives that help to protect against oxidation and corrosion.

● Sealing: Lubricants help seal the space between the piston rings and the cylinder wall to maintain combustion efficiency.

Aircraft Lubrication System Components

Commercial, business, and general aviation aircraft are usually fitted with either a wet sump or a dry sump lubrication system. The design of the system determines where the oil is stored, how it is distributed and cooled.

● Oil Reservoir: The oil is stored in the engine crankcase in a wet sump system. In a dry sump system, a separate oil tank is used. Dry-sump systems offer better temperature regulation and often allow a greater capacity of oil to be stored.

● Oil Pump: The pump is the circulatory system’s heart. It maintains a constant pressure and flow of oil throughout the system. In a dry sump system, a series of scavenge pumps are used to return oil to the external tank.

● Oil Filter: Filters out impurities, keeping them from recirculating through the system. Oil filters are usually replaceable, and some have a bypass valve to allow lubrication in the event of a blockage.

● Oil Cooler: Removes excess heat from the lubricant to help maintain the correct viscosity, especially important in high-performance engines and turbine engines.

● Pressure and Temperature Sensors: Provide monitoring data to the pilot and maintenance crew. Unusual or off-normal readings can indicate oil starvation, pump failure, or overheating issues.

A thorough working knowledge of these components can only come from a detailed syllabus, as the curriculum used by a Flight School Hong Kong for example. These facilities have long combined their student training programs with an emphasis on technical systems knowledge.

The Importance of Proper Lubricant Choice

As its name suggests, aircraft engine oils are not a one-size-fits-all commodity. Engine type, altitude, and climate affect lubricant choice. Other critical properties of oil are as follows:

● Viscosity: The relative flow characteristics of a lubricant. It must be thick enough to form a protective film, but fluid enough to circulate without restriction.

● Thermal Stability: Engine oils must be stable and retain their properties over a wide temperature range.

● Additives: Anti-wear agents, detergents, dispersants, and corrosion inhibitors are commonly used.

● Material Compatibility: Engine oils must be compatible with other engine materials, such as rubber seals and metals.

Aviation engine lubricants are generally of two basic types: mineral oils and synthetic oils. Mineral oils are most commonly used in piston-engine aircraft, particularly for break-in periods. Turbine engines are usually lubricated with synthetic oils, as they are better at resisting high temperatures.

Maintaining the Lubrication System

Maintenance and care of an aircraft’s lubrication system are critical to engine health and safe flight operations. Best practices include:

● Oil Changes: Replace the engine oil at the manufacturer’s recommended intervals. In general, this is between 25 and 50 hours of flight time, depending on the aircraft.

● Oil Analysis: Periodically send an oil sample to a lab for analysis. Spectrometric testing can provide early warning of engine wear or contamination.

● Pre-Flight Checks: Ensure oil levels are correct, and check for no visible leaks or discolouration.

● Monitoring Engine Instruments: A sudden loss of oil pressure or an increase in oil temperature during flight is a serious warning sign that requires immediate action.

Attention to these details comes early in a pilot’s training. For example, during a recreational pilot licence Melbourne course. There, even novice students learning to fly light aircraft are required to demonstrate engine awareness.

Turbine Engine Lubrication

Turbine engines can run at speeds and temperatures far in excess of piston engines. These characteristics necessitate a much more complex lubrication system. In turbine engines, this system is designed with the following features:

● Synthetic oils that can tolerate temperatures in excess of 200 °C (392 °F).

● A series of scavenge pumps for the rapid return of oil from bearings and gearboxes.

● Pressure relief and regulating valves to ensure optimal oil flow and prevent overpressure conditions.

The cost of lubrication system failure in turbine-powered aircraft is so great that redundant design features and constant system monitoring are part of the norm.

Advancements and Innovations in Aircraft Lubrication

Just as aircraft engines become more efficient and cleaner-burning, new lubrication technology is also emerging. Future trends include:

● Environmentally friendly lubricants: Lubricants that reduce the environmental impact of aircraft without degrading performance.

● Smart sensors: Integration with on-board digital systems to provide real-time monitoring of oil condition and predictive alerts to reduce unscheduled downtime.

● Nanotechnology: Nanoparticles in new oil additives are being developed to reduce friction and improve heat transfer.

The aircraft lubrication system is an unsung hero, quietly ensuring engines run smoothly, safely, and efficiently. From student pilots earning their recreational pilot licence in Melbourne to engineers working on commercial jets, understanding the principles and maintenance of lubrication systems is foundational to aviation success. In fact, mastering such technical knowledge is part of the professional development found in structured programs like those at a Flight School Hong Kong, where safety is rooted in deep system awareness.

Whether flying piston singles or twin turbines, knowing how the lubrication system supports your engine is not just useful—it’s essential to safe and effective aviation operations.