In many modern production lines, the role of a Differential Air Shaft has become essential for maintaining precision and stability in web handling processes. This specialized shaft is engineered to accommodate varying web tensions while ensuring that multiple rolls can unwind or rewind at consistent speeds. The innovation lies in its ability to adjust torque distribution automatically, reducing uneven material stress and guaranteeing smooth operations across different substrates such as films, paper, textiles, and laminates.

One of the standout features is the adaptability it brings to converting and packaging industries. Traditional shafts often struggle when handling materials with different thicknesses or elasticity. In contrast, this advanced technology allows operators to fine-tune performance, which helps minimize waste and improve efficiency. By supporting multiple slit widths, it provides flexibility in product design and manufacturing.

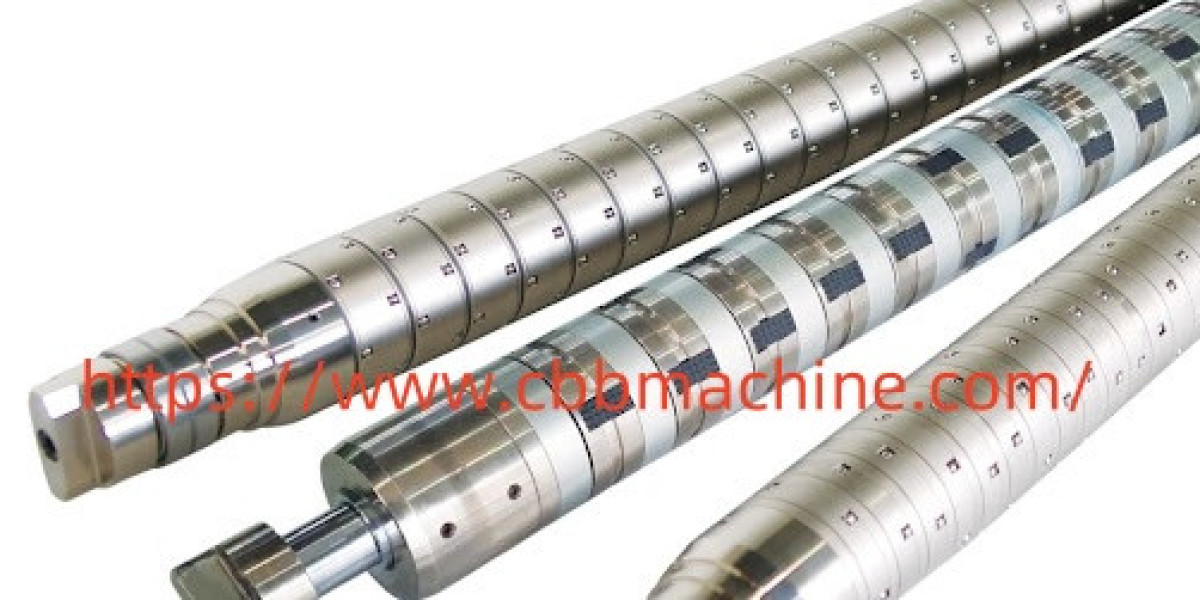

Durability and reliability further distinguish this system. Built with industrial-grade components, these shafts can withstand long hours of operation without compromising accuracy. The use of hardened steel and precision-balanced parts ensures long service life, reducing the frequency of replacements. For manufacturers, this directly translates to lower maintenance costs and higher uptime.

Safety is another core consideration. These shafts are designed to reduce the risks of web misalignment or sudden slippage, both of which can cause costly damage. By integrating features that secure rolls firmly, production lines can operate with greater confidence and reduced chances of defects.

In today's era of digital transformation, many designs are compatible with automated control systems. This allows for seamless integration into smart factories, where real-time monitoring and predictive maintenance enhance overall productivity. By collecting data during production, companies can forecast wear and plan servicing schedules more effectively, avoiding unexpected downtime.

Another major benefit lies in energy efficiency. With optimized torque control, less power is wasted, and smoother operation minimizes energy consumption. This not only reduces operational costs but also contributes to sustainability goals that are increasingly important for global industries.

In conclusion, while often hidden from view, these shafts play a pivotal role in ensuring quality, stability, and cost-effectiveness in various roll-to-roll processes. Their ability to balance adaptability, durability, safety, and integration with modern systems makes them an indispensable component in competitive manufacturing environments.

For more detailed insights, please visit https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html