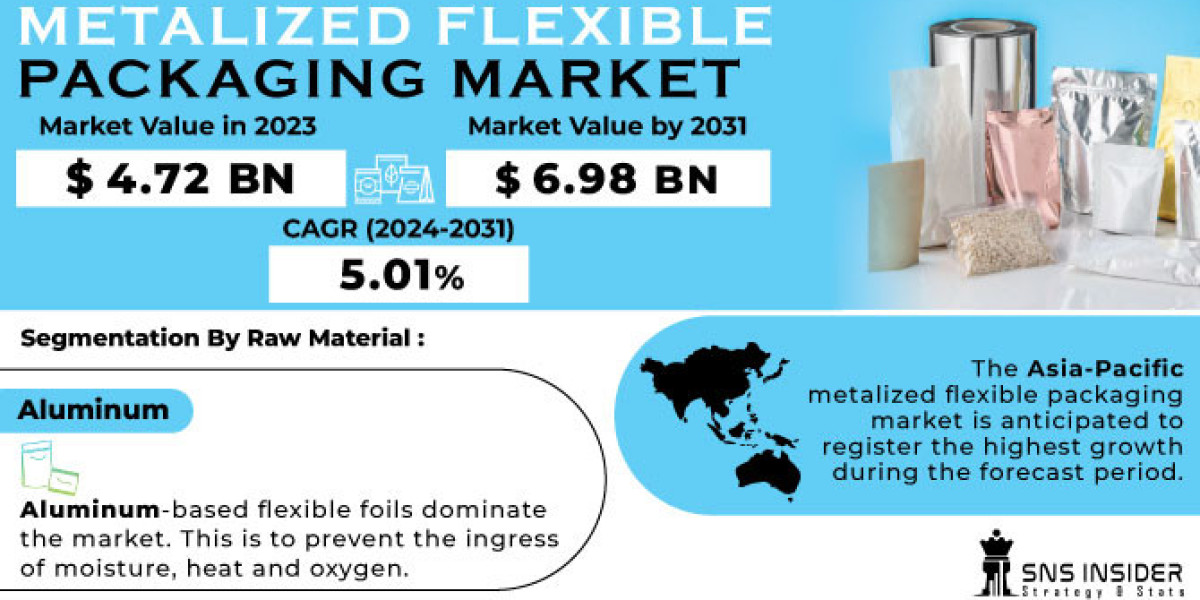

The global Metalized Flexible Packaging Market Report is on an upward trajectory, driven by increasing demand across various industries such as food & beverages, pharmaceuticals, and personal care. The , which was valued at USD 4.72 billion in 2023, is projected to reach USD 6.98 billion by 2031, growing at a compound annual growth rate (CAGR) of 5.01% from 2024 to 2031.

Overview

Metalized flexible packaging is a type of packaging that combines the benefits of both metal and flexible materials. It offers superior barrier properties, protecting products from light, oxygen, and moisture, which is crucial for preserving the freshness and extending the shelf life of products. The versatility and durability of metalized flexible packaging have made it a popular choice among manufacturers and consumers alike.

The 's growth is primarily driven by the increasing demand for convenient, lightweight, and visually appealing packaging solutions. As consumer preferences shift towards on-the-go products and single-serve packaging, the need for flexible and protective packaging materials has surged. Metalized flexible packaging meets these demands while also offering cost-effective solutions for manufacturers.

Segmentation

The metalized flexible packaging can be segmented based on raw material, packaging type, structure, end-use, and region.

By Raw Material:

Aluminium: Aluminium is the most commonly used raw material in metalized flexible packaging due to its excellent barrier properties and lightweight nature. It is widely used in the packaging of food, beverages, pharmaceuticals, and personal care products. The recyclability of aluminium is an added advantage, contributing to the sustainability of metalized flexible packaging.

Chromium: Chromium is used in metalized flexible packaging to enhance the material's strength and resistance to corrosion. It is particularly valued in applications where packaging needs to withstand harsh environmental conditions. The use of chromium in packaging is more prevalent in the pharmaceuticals and personal care sectors.

Nickel: Nickel is another raw material used in metalized flexible packaging, known for its durability and resistance to high temperatures. It is often used in applications where packaging needs to maintain its integrity under extreme conditions. The demand for nickel-based packaging materials is growing in the food & beverages and pharmaceuticals industries.

By Packaging Type:

Wraps: Metalized wraps are commonly used in the packaging of confectionery, snacks, and baked goods. They provide an effective barrier against moisture and oxygen, ensuring the freshness and quality of the products. The use of metalized wraps is increasing in the food & beverages industry, driven by the growing demand for convenient and visually appealing packaging.

Bags: Metalized bags are widely used in the packaging of coffee, tea, and other dry goods. They offer excellent protection against light and moisture, which is essential for preserving the aroma and flavor of the products. The demand for metalized bags is rising, particularly in the premium food segment.

Pouches: Metalized pouches are gaining popularity in various industries, including food & beverages, pharmaceuticals, and personal care. They are lightweight, durable, and provide an effective barrier against environmental factors. The flexibility and convenience offered by metalized pouches make them a preferred choice for packaging a wide range of products.

Roll Stock: Roll stock is used in the production of various types of packaging, including bags, pouches, and wraps. Metalized roll stock is valued for its versatility and ease of use in automated packaging processes. The growing demand for efficient and cost-effective packaging solutions is driving the use of metalized roll stock in the .

Others: This segment includes other types of metalized flexible packaging, such as sachets, labels, and liners. These packaging types are used in niche applications across various industries, contributing to the overall growth of the metalized flexible packaging .

By Structure:

Laminated: Laminated metalized flexible packaging consists of multiple layers of materials, providing enhanced barrier properties and durability. Laminated packaging is widely used in the food & beverages industry, where the preservation of product freshness is critical. The growing demand for high-performance packaging solutions is driving the adoption of laminated metalized flexible packaging.

Mono Extruded: Mono extruded metalized flexible packaging is made from a single layer of material, offering a cost-effective solution for packaging applications. It is commonly used in the packaging of snacks, confectionery, and other food products. The simplicity and recyclability of mono extruded packaging are key factors contributing to its popularity.

Others: This segment includes other structures of metalized flexible packaging, such as co-extruded and multi-layered packaging. These structures offer specific benefits tailored to the needs of different industries, such as enhanced strength, flexibility, and barrier properties.

By End Use:

Pharmaceuticals: The pharmaceuticals industry is a significant end-user of metalized flexible packaging, where the protection of products from environmental factors is crucial. Metalized packaging ensures the safety and efficacy of pharmaceutical products by providing a robust barrier against light, moisture, and oxygen. The growing demand for secure and reliable packaging in the pharmaceuticals industry is driving the growth of this segment.

Food & Beverages: The food & beverages industry is the largest end-user of metalized flexible packaging. The need to preserve the freshness, flavor, and quality of food products has led to the widespread adoption of metalized packaging solutions. The increasing demand for convenient and sustainable packaging in the food & beverages sector is expected to continue driving the 's growth.

Personal Care: The personal care industry is another major end-user of metalized flexible packaging. Products such as cosmetics, skincare, and haircare require packaging that not only protects the contents but also enhances the product's visual appeal. Metalized flexible packaging offers a combination of durability, protection, and aesthetic appeal, making it a preferred choice in the personal care industry.

Others: This segment includes other industries that use metalized flexible packaging, such as electronics, household products, and industrial applications. The versatility and protective properties of metalized packaging make it suitable for a wide range of applications, contributing to the overall growth of the ..

Regional Analysis

The metalized flexible packaging is witnessing growth across all major regions, with significant opportunities in both developed and emerging s.

North America: North America is expected to hold a significant share of the metalized flexible packaging , driven by the region’s strong food & beverages and pharmaceuticals industries. The presence of major packaging manufacturers and the growing demand for sustainable packaging solutions are contributing to growth in the region.

Europe: Europe is another major for metalized flexible packaging, with countries like Germany, France, and the UK leading the adoption of innovative packaging solutions. The region's focus on sustainability and the circular economy is driving demand for recyclable and metalized flexible packaging materials.

Asia-Pacific: The Asia-Pacific region is anticipated to experience the fastest growth in the metalized flexible packaging , driven by rapid industrialization, urbanization, and increasing consumer demand for packaged products. Countries like China, India, and Japan are investing in advanced packaging technologies, boosting the demand for metalized flexible packaging.

Latin America: Latin America is also witnessing growth in the metalized flexible packaging , driven by the expansion of the food & beverages and personal care industries. The region's growing middle-class population and increasing consumer spending are contributing to the demand for high-quality packaging solutions.

Middle East & Africa: The Middle East & Africa region is gradually adopting metalized flexible packaging solutions, driven by the need for effective packaging in the food & beverages and pharmaceuticals industries. The region's is expected to grow as more companies invest in advanced packaging technologies.

Competitive Landscape

The metalized flexible packaging is highly competitive, with several key players driving innovation and growth. Companies such as Amcor Limited, Sealed Air Corporation, Mondi Group, Tetra Pak International S.A., and Huhtamaki Group are leading the with their extensive product portfolios and commitment to sustainability.

These companies are focusing on research and development to create innovative metalized flexible packaging solutions that meet the evolving needs of consumers and comply with regulatory standards. Strategic partnerships, mergers and acquisitions, and investments in advanced technologies are common strategies employed by these leaders to strengthen their position.

Future Outlook

The metalized flexible packaging is set to witness significant growth over the forecast period, driven by increasing demand across various industries and the ongoing development of advanced packaging technologies. As companies continue to innovate and invest in sustainable packaging solutions, the is expected to expand, offering new opportunities for growth and development.

Conclusion

The metalized flexible packaging is on a robust growth trajectory, with a promising future ahead. Companies that embrace innovation and sustainability are well-positioned to capitalize on the growing demand for metalized flexible packaging solutions, ensuring long-term success in this dynamic and evolving .

Read More Details @ https://www.snsinsider.com/reports/metalized-flexible-packaging-market-3127

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)